Attention Users Of LPG Forklifts! Watch Out For Low Quality Gas (Low Quality LPG)

IMPORTANT INFORMATION FOR LPG USERS

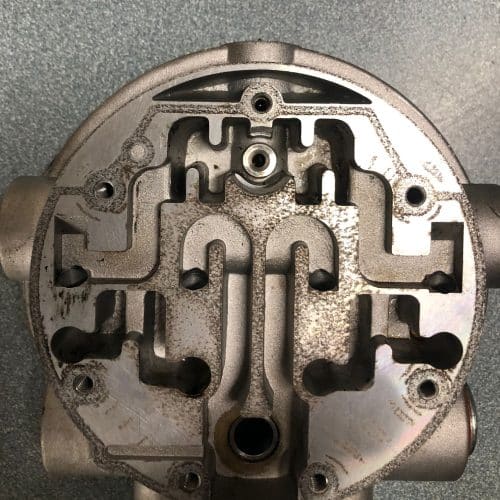

Above are some pictures of a gas unit that is only 4 weeks old and the tar build-up is unusually immense. Luckily we managed to get it cleaned and operational for the customer!

We have recently become aware of ongoing LPG quality issues in the UK.Numerous customers have been contacting us regarding starting problems with their LPG forklift trucks.

THE HSE'S LATEST UPDATE

The Health and Safety Executive (HSE) recently issued an update regarding LPG forklift truck fire risks. They highlighted concerns about numerous reported fires on and around LPG-powered forklift trucks during starting, often linked to the build-up of deposits in fuel systems, particularly in vaporiser units.

The update emphasised mechanical issues such as deposits causing starting failures, affecting flow regulators and shut off valves, and leading to sticking valves that create a rich mixture unable to ignite. Starting failures, especially in cold conditions, were a significant point of focus, with trucks not starting due to sticking valves caused by deposit build-up.

The HSE highlighted the danger of unburned LPG posing a fire hazard. When starting attempts fail, unburned LPG can be released, potentially gathering in low areas and igniting from various sources due to its tendency to sink.

WHY IS THIS LOW QUALITY LPG SUPPLY OCCURRING?

The root of the issue lies in the poor quality of LPG supplied by liquid gas companies. The problem arises from residues present in the liquid gas, which result in the formation of heavy tar deposits on the relief valve in the LPG regulator/vaporizer. Consequently, the gas-air mixture becomes excessively rich, causing many users to encounter difficulties in starting their LPG forklifts or experiencing rough running. In some cases, the issue may also lead to a noticeable gas odour emanating from the forklift due to the relief valve being stuck open.

While this problem is affecting our customers in the UK, it has also been reported in various regions across Europe.

HOW SHOULD I TAKE ACTION?

If you own an Liquid Petroleum Gas Forklift Truck and it fails to start after a few attempts, it is important not to persistently try starting the machine. Continuing to do so poses a safety hazard and can result in significant damage, expensive repairs, and potential harm to the user. Repeated attempts to start the gas forklift can lead to the formation of an explosive gas-air mixture in the engine compartment and its immediate surroundings.

IF YOUR LPG FORKLIFT TRUCK REFUSES TO START, FOLLOW THESE STEPS

- Refrain from further attempts to start the vehicle.

- Close the shut-off valve on the gas bottle or tank.

- Notify us (or your service partner) to request an inspection and, if necessary, repairs.

Any customers experiencing problems can contact us as their first point of contact so that we can assist in resolving the issue. Please feel free to call us on +44(0)121 500 5009 for assistance and additional information, as well as access to our forklift breakdown and repair service.

Furthermore, whenever possible, we strongly urge customers to voice their complaints to their LPG bottle suppliers. It is crucial for safety reasons that gas companies import gas of acceptable quality, and putting pressure on the concerned companies is the most effective way to drive change and prevent users from incurring costly repairs.

FORKLIFT BREAKDOWN & REPAIR SERVICE:

Here at AtlasForklift we don't just supply forklift fleets for contract hire and lease purchase, we also provide a comprehensive forklift truck & work truck breakdown and repair service. Our team of experts are excellent at identifying issues with forklifts through comprehensive, safety-lead troubleshooting and repairs of any issues we discover. You can call us directly or if you wish you can find out more about our breakdown and repair service by clicking "More Information".